Features and hints

Personal Protective Equipment (PPE)

In the European Union (EU), Regulation (EU) 2016/425 on Personal Protective Equipment regulates the testing and certification of Personal Protective Equipment (PPE), including that of ASATEX AG. According to this regulation, manufacturers of PPE must ensure that their products comply with the relevant health and safety requirements before they are placed on the market.

ASATEX AG has its PPE tested by conformity assessment bodies. These can be independent testing institutes or bodies officially recognised by the member states of the EU. These bodies carry out extensive tests, assessments and checks to ensure that the PPE meets the strict requirements of the regulation.

ASATEX AG ensures that its PPE products are correctly certified and labelled before they are placed on the market. Employers are required to select the most appropriate PPE for the specific working conditions and to ensure that it is correctly used, maintained and renewed when necessary. This will ensure comprehensive protection of workers in different working environments.

Personal Protective Equipment (PPE) Categories

Personal Protective Equipment (PPE) categories provide an essential foundation for protecting employees and workers in various occupational environments. PPE covers a wide range of protective equipment designed to ensure the health and safety of those working in hazardous work environments. Categories of PPE are structured according to specific risks and requirements and play a central role in the selection, use and maintenance of appropriate protective equipment.

Category 1: Low protection

Category 1 of personal protective equipment (PPE) covers protective measures designed to protect against minor risks and hazards. This category concerns situations where the risk of injury is considered minimal. It includes simple PPE that is comfortable and easy to use without requiring special instructions or training.

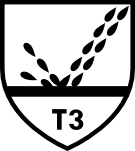

Category 2: Moderate protection

Category 2 of personal protective equipment (PPE) concerns situations where moderate risks and hazards may occur. This category includes protective equipment that provides a higher level of protection than category 1 and is designed for work environments where the risk of injury, while not extremely high, is significant.

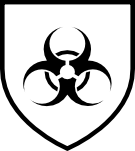

Category 3: High protection

Category 3 of personal protective equipment (PPE) is dedicated to protection against serious risks and hazards that may pose significant health risks or even life-threatening situations for wearers. This category concerns working environments where particularly hazardous conditions, such as extreme heat, radiation, chemical contamination or biological hazards, may occur.