Cold protection in PPE – reliable winter workwear

Working in low temperatures affects bodily functions after only a short time. Motor skills, concentration and responsiveness quickly deteriorate, significantly increasing the risk of minor operating errors and even serious injuries due to falls or hypothermia. In addition, personal protective equipment (PPE) often has to meet several requirements at the same time. Modern cold protection clothing combines these protective functions in a sophisticated system, ensuring that employees can carry out their tasks safely, efficiently and in good health.

In this article, you will learn:

Dangers posed by exposure to cold

Cold affects the body and behaviour. The consequences range from temporary loss of performance to serious health damage.

Health risks

- Hypothermia: When the core body temperature drops, motor and mental abilities decline. Severe hypothermia is life-threatening.

- Local frostbite: Extremities (fingers, toes, nose, ears) are particularly susceptible. In severe cases, irreversible damage to tissue and nerves may occur.

- Chilblains and cold sores: Redness, swelling and itching, often painful and protracted.

- Stress on the cardiovascular system: Cold reactions such as vasoconstriction increase blood pressure, which is particularly relevant for people with pre-existing heart conditions.

- Respiratory diseases: Cold, dry air promotes irritation and increases the likelihood of respiratory infections.

- Joint problems: Frequent exposure to cold can damage the joints over time and lead to restricted movement.

Safety and performance risks

- Delayed emergency responses: Reduced concentration and alertness can prevent quick reactions.

- Risk of falling and slipping: The risk of accidents increases significantly on icy or wet surfaces.

- Uncertain tool guidance: Cold-induced muscle stiffness and reduced grip strength increase the risk of operating errors.

How moisture and wind exacerbate cold damage

Wet clothing loses its insulating effect because water displaces the air trapped in the fibres. The problem with this is that air is a very poor conductor of heat, whereas water conducts heat much better. This means that if clothing is damp, body heat can be conducted to the outside more quickly.

In addition, wind causes the body to cool down more quickly because it continuously blows away the warm layer of air around the body and replaces it with cooler air. This effect is known as the wind chill effect and increases with increasing wind speed.

Overview of cold protection standards

Protective clothing: In order to protect against these and other hazards, the EN 342 and EN 14058 standards specify test requirements and key figures that can be used to objectively assess the protective effect of clothing against cold.

EN 342 applies to temperatures of less than or equal to -5 °C, while EN 14058 applies to temperatures above -5 °C. In addition to low air temperature, both standards also take humidity and wind speed into account.

Protective gloves: In the area of cold protection gloves, the following applies.

Protective gloves: Cold protection gloves are subject to their own standard, EN 511, which assesses the protection provided by gloves against convective cold (air) and contact cold (touch). The pictogram for cold protection gloves features a three-digit code, the digits of which indicate the respective performance level:

- First digit (convective cold): The performance level (0–4) indicates resistance to passing cold.

- Second digit (contact cold): The performance level (0–4) describes thermal resistance in direct contact with a cold object.

- Third digit (water resistance): Performance level 0 means water penetration after 30 minutes, performance level 1 means no water penetration.

Protective measures: organisational, technical, personal (TOP principle)

Various technical, organisational and personal measures can be implemented to ensure that work areas remain safe even in extreme weather conditions.

Technical measures ensure that workplaces remain safe at all times. Windbreaks, temporary canopies or weatherproof work tents reduce the direct impact of wind and cold on employees. Local heating sources or radiant heaters create warm work and break areas where employees can quickly recover. Non-slip surfaces or effective floor dehumidification prevent falls on icy or wet surfaces and thus make a significant contribution to occupational safety.

Organisational measures control how long and under what conditions employees are exposed to the cold. Careful risk assessment allows the duration of exposure, work intensity and environmental conditions to be accurately recorded. On this basis, working hours and rotations can be adjusted, planned warm-up breaks can be incorporated, or deployment plans can be made flexible in extreme weather conditions. Regular health checks ensure that signs of cold stress are detected at an early stage so that countermeasures can be taken in good time.

Personal measures ensure the direct protection of each employee and are effective regardless of external circumstances or organisational measures. They can be flexibly adapted to different activities, exposure times and weather conditions, ensuring optimum individual protection. This protection is achieved through suitable personal protective equipment, such as winter-proof work gloves, cold-protection-certified high-visibility jackets and trousers, or multi-standard workwear that meets several requirements at once.

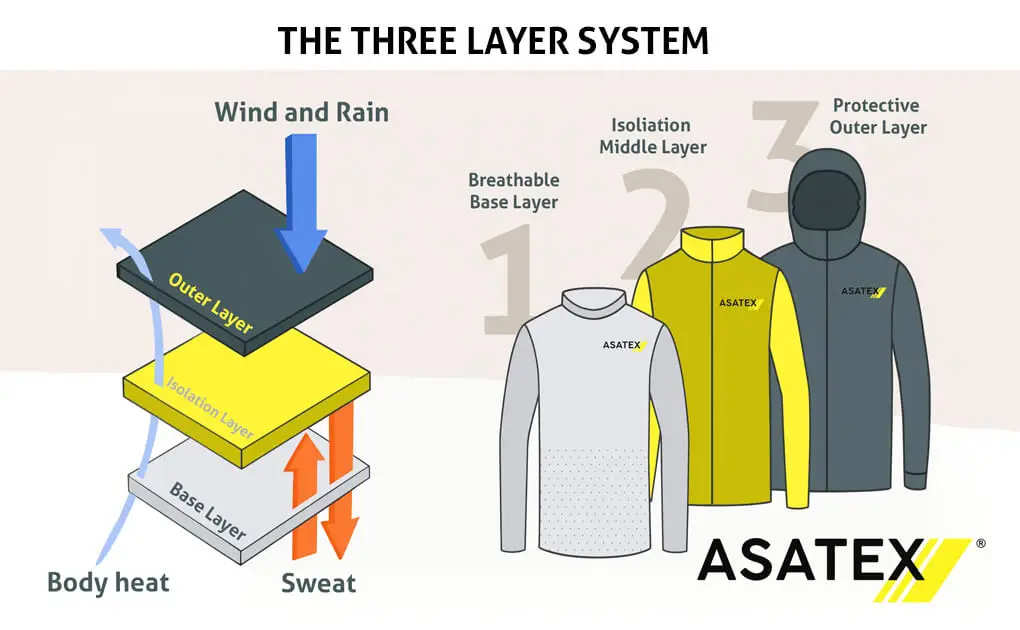

Structure concept: Layering system

The three-layer system is a proven principle in which three layers of clothing are worn on top of each other to wick away moisture, retain heat and protect against wind, rain or snow. This system is particularly flexible, as the individual layers can be adjusted depending on weather conditions and activity level.

The base layer lies directly on the skin and has the task of efficiently wicking away sweat. Breathable materials such as polyester, polyamide and polypropylene are therefore ideal. Certain natural fibres, such as merino wool, also have excellent moisture-regulating and insulating properties and would therefore be suitable for the base layer in principle. However, as aspects such as price, care requirements and, last but not least, animal welfare should also be taken into account when choosing materials, natural fibres are only used to a limited extent for cold protection. Even cotton is only suitable for cold protection to a limited extent, as it wicks relatively little moisture away from the body.

The insulation layer serves to store body heat and prevent heat loss to the environment. Commonly used materials include fleece, down and wool. Fleece, a roughened fabric usually made of polyester, is lightweight, highly breathable, quick-drying and easy to care for. In addition, its rough structure traps air, whose naturally poor thermal conductivity forms a particularly effective thermal barrier.

The weather protection layer protects against wind, rain and snow and prevents moisture from penetrating the clothing system from the outside. Typical solutions are hardshells (waterproof, highly abrasion-resistant membrane or coated fabrics) and softshells (wind and water-repellent, significantly more breathable). Key properties are waterproofing (membranes/laminates or PU coatings, sealed seams), breathability (for wicking away body moisture during activity), abrasion and seam strength, and functional details such as hoods, ventilation openings and adjustable cuffs. The choice depends on the intended use: for high physical exertion, a highly breathable, slightly water-repellent solution is often advisable, while for prolonged exposure to precipitation, fully waterproof, welded systems are often preferable.

Note: PPE often has to meet several requirements at once, such as increased visibility, antistatic properties or chemical protection. Modern cold protection clothing combines these functions in a coordinated system, meaning that material compromises are sometimes unavoidable.

Conclusion

Cold protection is an important part of occupational safety: it prevents damage to health, reduces the risk of accidents and ensures productivity in the workplace. Employers can protect their employees efficiently by conducting a thorough risk assessment, implementing appropriate organisational and technical measures, and using multifunctional cold protection PPE. Investments in suitable clothing, care and organisation pay off in the long term through reduced downtime and increased safety.

FAQ

When does EN 342 apply and when does EN 14058 apply?

EN 342 applies to clothing systems for very cold conditions (typically ≤ −5 °C), while EN 14058 assesses clothing for moderate cold conditions (above −5 °C). The choice of standard depends on the intended use and the environmental conditions.

What does the EN 511 marking on gloves mean?

EN 511 assesses gloves against convective cold (digit 1), contact cold (digit 2) and water resistance (digit 3). The combination of the three digits provides information about the performance level and application limits of a cold protection glove.

How does the three-layer system (layering) work?

The system consists of a moisture-wicking base layer, a warming insulation layer and a windproof/waterproof weather protection layer. By combining these layers, insulation, breathability and protection against environmental influences can be optimally adjusted.

How do I properly care for and maintain cold protection PPE?

Follow the manufacturer's instructions for washing, impregnation and storage. Insulation materials and membranes can be sensitive, so proper care and regular checks help to extend their protective effect and service life.

Which ASATEX products provide reliable protection against the cold?

At ASATEX, you will find winter-proof work gloves, cold-protection-certified high-visibility jackets and trousers, and multi-standard workwear. On request, we can advise you individually on selection, the right size and integration into your protection concept.